Our goal is to provide the best possible service to our customers worldwide, assuring on time delivery of high quality products. In order to reach this goal, we created our own supply mall, which categorises our manufacturers with reference to needs of our customers. For instance, NOS stands for Never on Stock, which indicates very low cost products in high quantities. When we receive a client inquiry for high quantities at low prices, we already have a portfolio of manufacturers, who are capable of meeting such demands.

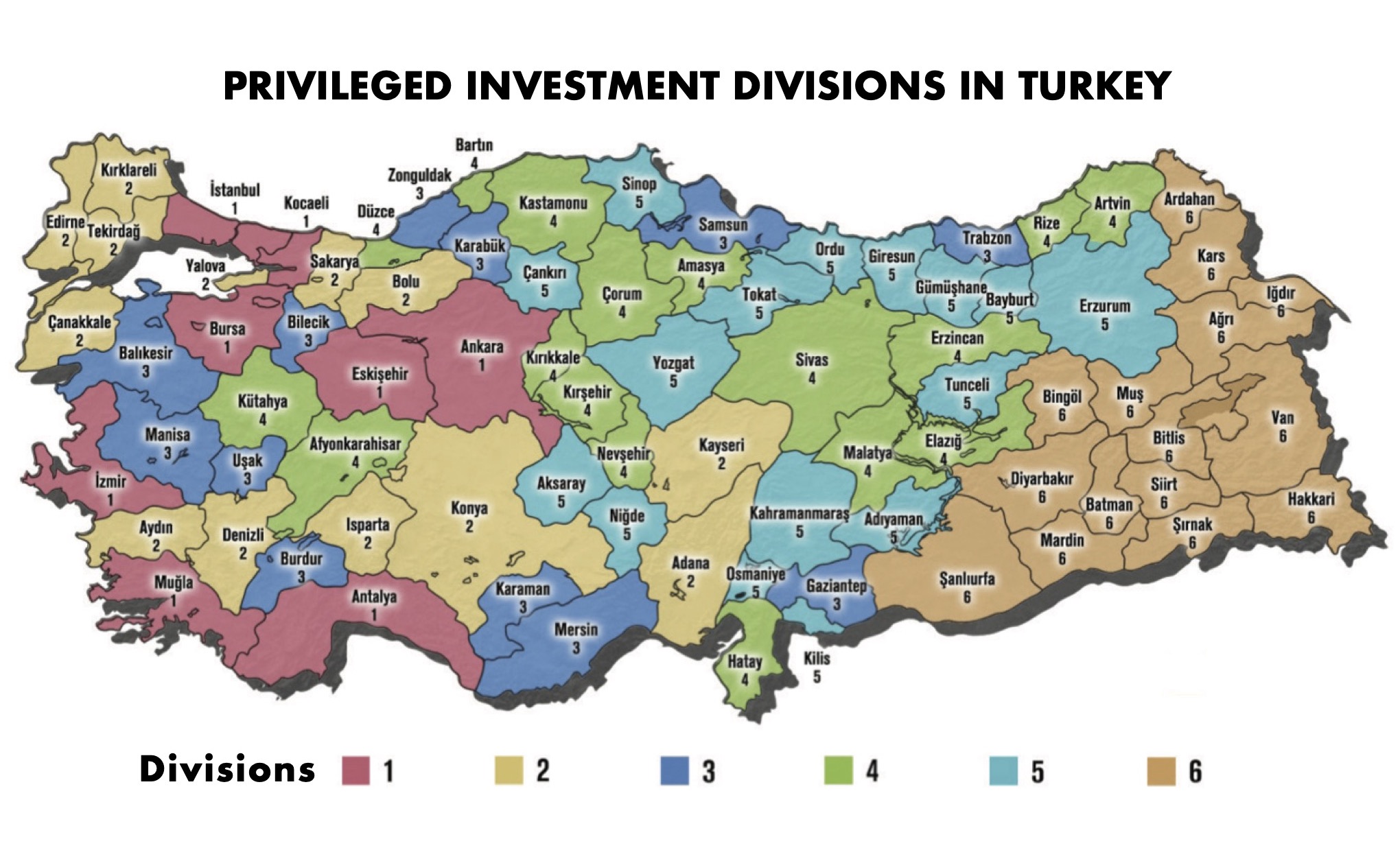

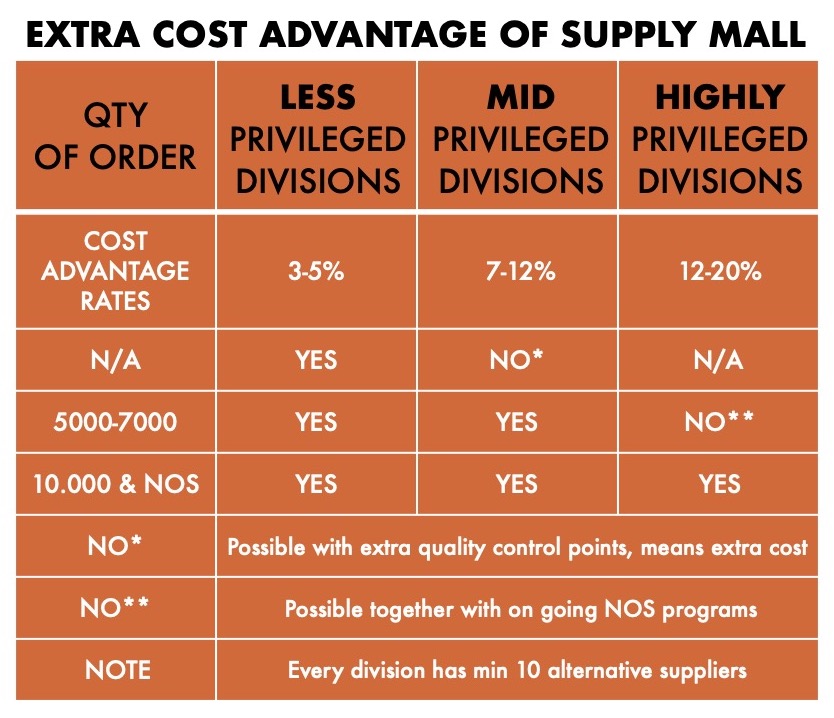

Within this framework, we divided Turkey into 6 zones, each presenting certain advantages with respect to order quantity. As a rule of thumb, at higher quantities the further east we go for production, the higher the price advantages may be. Depending on the government subsidies for producers in certain regions of Turkey, respective cost advantages may vary between 3-20 %.

In order to utilise these cost advantages, certain requirements has to be met:

- Having the ability to manage local culture due to long years of experience in doing business throughout Turkey.

- Having detailed information on production capabilities of each region to determine the right region for each customer.

- Having the customer’s target prices at the very beginning of the process, in order to carry out the sampling & create a price competition between suppliers.

- In the long run, it is crucial to have order continuity at certain quantities, which will strengthen our hand vis a vis local manufacturers.

We developed a simplified map of 6 different production zones in Turkey. The chart further divides these zones into three and highlights price advantages linked to the quantity of orders. While zone 1 allows production of fairly low quantities, zone 6 requires orders in high quantities. Consequently, prices in zone 1 will be higher than in zone 6.

It is crucial for us to know the exact expectations of our customers (target prices, quantities, quality expectations, etc.) to be able to determine best regions for production and to offer best possible prices.

Our perspective is always to form a long-lasting business relationship. Thus it is of utmost importance for us to provide the best service within our capability and lead our customers through a hassle free process.

Supply Base

We work countrywide with around 60 manufacturers. It is of utmost importance to us that all our manufacturers comply with internationally required industry standards and certifications, such as BSCI, Sedex, etc. Every single one of the manufacturers we work with has been monitored with care and selected according to highest international standards.

Fashion Input

Our design team is constantly monitoring new trends in graphics, washing, fabric, accessories, models and manufacturing processes. We utilise this information to create new ideas for the collections of our customers.

Sourcing

Our team relentlessly monitor new fabrics, new washing techniques, accessories, printing techniques, etc. At the same time, we constantly add new manufacturers to our portfolio, to be able to offer the best price-quality ratio in all services we provide to our clients.

Merchandising

Once we receive all the details regarding your prospective order, we need 10 days for the preparation of samples and R&D of additional product details. Samples are prepared free of charge; only shipping would have to be covered by your side. Should we reach to the agreement stage, a final set of production samples would be provided at a cost to you. Only after the approval of these samples, production would commence.

Quality Control

The quality control process starts with standard fabric tests, followed by more detailed controls during each production phase (sewing, ironing, packaging, etc.) and final controls according to AQL standards.

Social Compliance

Social audits of all manufacturers we work with are periodically carried out by our auditors so that any possible shortcomings are found out and required improvements are promptly implemented.